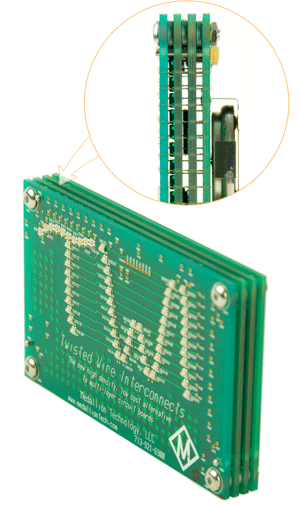

|

Double Sided PCBs Assembled with TWIs

[Stack Thickness = 0.396”/4 PCB Layers] |

The Twisted Wire Interconnect is very simple by design; the material consists of BeCu multi-filament that has been gold-plated to provide superior electrical interconnection. The physical construction comprises the multi-filament brought together and stranded into a 1 x 6 wire configuration.

The spooled wire is then introduced to the TWI-2100 manufacturing system that forms the interconnect bulges precisely along the length of the stranded wire. The TWI-2100 is a fully automated high volume system that can produce a typical four bulge (4 I/O) configuration within 1.5 seconds. As they are being manufactured, the TWI’s are then singulated into a cartridge system that provides seamless introduction to the assembly system downstream.

The TWI provides the industry with a major breakthrough in solderless, high density, true Z-axis interconnect. Medallion has developed a novel way to interconnect electronics using the patented TWI. The method greatly improves upon traditional circuit board construction by converting complex multi-layer circuit boards to a series of simple, inexpensive, double-sided boards. The process is simple and can be utilized in any design where multiple PCBs require interconnection between each other.